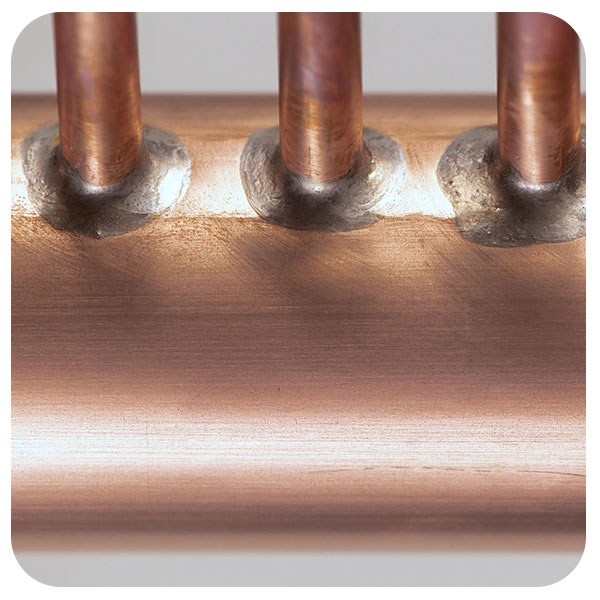

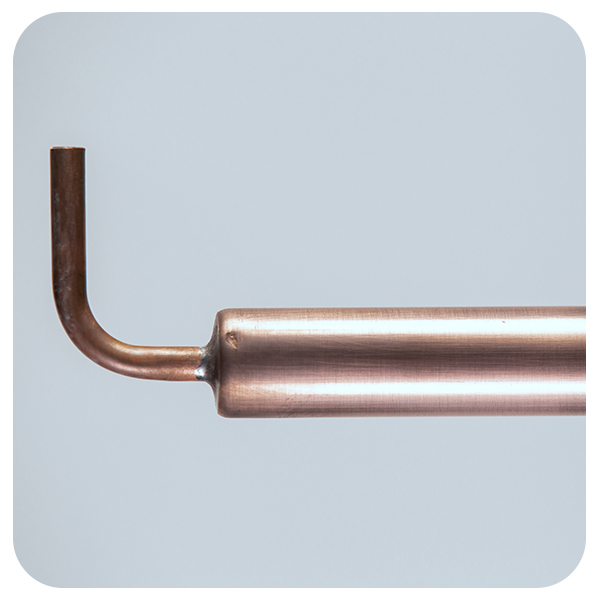

Lantery’s manifolds are produced in CNC equipment, with less than 0,1mm tolerance, granting precision and quality in the final assembly of the heat exchangers. Lantery uses a precision Flow Drill type product (also produced by CMS) to produce headers with perfect hole alignment and precise formation of collars. This allows better penetration of solder upon brazing of the coil stubs in the header assembly. The CMS end forming process used by Lantery provides a flat or slightly convex closure which avoids drain or weld plugs and provides a uniform and highly precise end closure for the headers.

Telephone: +55 11 4529-3197

Telephone: +55 11 4529-3197 Email:

Email: